Dongguan Kaichuang Precision Machinery Co., Ltd, founded in 1983, is an experienced manufacturer of various metal forming and fabrication machines. We have been specializing in R&D, production and sales of various spring machines for nearly 4 decades. Our spring machines are mainly used to process wires with a diameter of 0.12mm to 10.00mm, including camless CNC spring making machine, high speed spring coiling machine, automatic wire feeding machine, tufting machine and accessories.

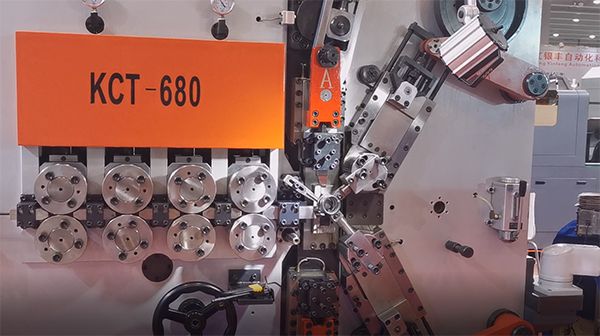

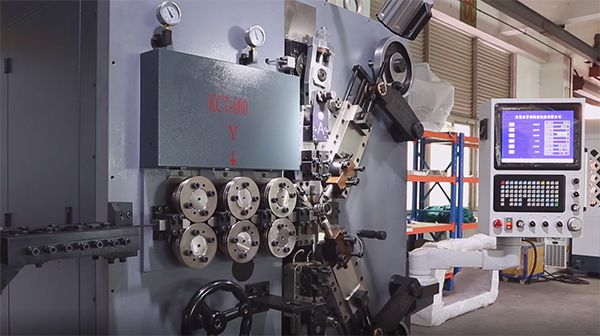

To provide high quality, stable and reliable spring machines, our company has introduced Taiwan CNC control system, Japanese Sanyo/Yaskawa servo motor, Taiwan controller and German bearings. Featuring high feeding precision, stable and accurate forming, our spring machines are useful for producing all kinds of springs, including left/right-handed cylinder-shaped compression/tension/torsion springs, single cone spring, convex concave spring, lock spring, special-shaped spring and forming of complex parts. Our products have been sold to domestic and overseas markets and are well welcomed by our clients.

Our spring machines serve a wide range of industries, like automotive, electronic, electric appliance, stationery, bathroom accessories and other industries. In the increasingly competitive global market, KCMCO will continue, as always, to serve the domestic and international customers with excellent quality, reasonable and competitive price, on-time delivery and complete after-sales service.

To better control the product quality and precision, our machining workshop is equipped with milling machine, drilling machine, grinding machine, lathe and other machining equipment. Thus, we have the capacity to independently produce the parts for spring machines, including tool holder, slide, mandril, feed wheel, wire feed axis, wire feed guide.

Assembly workshop consists of electrician and bench worker working stations.

Electrician is responsible for circuit connecting, product powering and electrical safety.

Bench worker is in charge of the product structure arrangement and mechanical equipment assembly.

After the assembly of product, at least 48-h operation is required for the spring machines to check if there are mechanical problems. Then, technicians begin to commission and produce samples according to customer products.