5-Axis CNC Spring Forming Machine

5-Axis CNC spring forming machine comes with 5 axes, including cam, feed, quill, wire rotation and spinner shaft (optional).

This spring former is able to handle wires in a diameter of 1.2-4.0 mm and 0.3-2.5mm, with a maximum feeding speed of 120m/min. It is usually used to produce compression spring, tension spring, torsion spring, scroll spring, tower spring, special-shaped spring, as well as line forming and bending forming products, and other complex products.

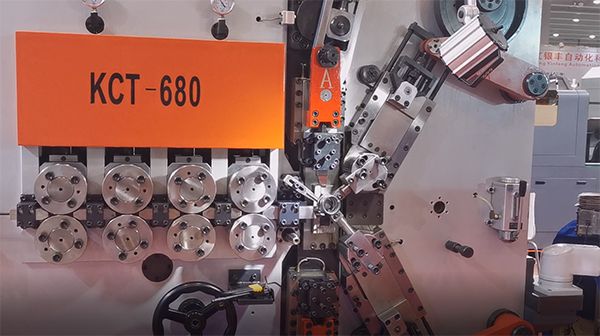

1.2-4.0mm Spring Forming Machine, CNC Control, 5-axis, KCT-0535WZ

- Model: KCT-0535WZ

- Number of Axis: 5

- Wire Diameter: ⌀ 1.2-4.0mm

- Max. Outer Diameter: ⌀ 80mm

- Max. Wire Feed Speed: 120 m/min

- Max. Production Rate: 60 pcs/min

- Feed Roller: 2 Groups

- Feed Servo Motor: 4.5 kW

- Quill Servo Motor: 1.8 kW

- Wire Rotation Servo Motor: 4.5 kW

- Cam Servo Motor: 2.7 kW

- Spinner Servo Motor: 1.0 kW

- Air Compressor System (Air pressure): 0.2-0.4 Pa

- Air Compressor System (Air cylinder): 5

- Air Compressor System (Probe): 5

- Power: 3P 380V 50/60Hz

- Dimension (L*W*H): 2400*1700*1900 mm

- Weight: 2500 kg

Request a quote

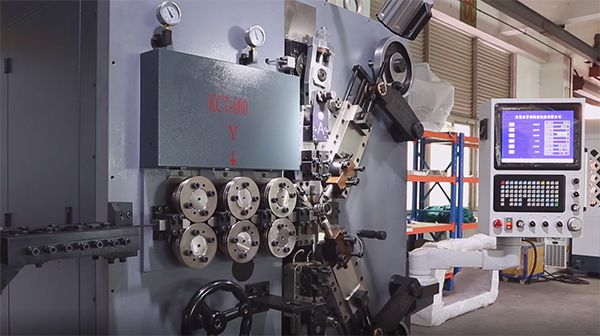

0.3-2.5mm Spring Forming Machine, Computer Controlled, 5-axis, KCT-0520WZ

- Model: KCT-0520WZ

- Number of Axis: 5

- Wire Diameter: ⌀ 0.3-2.5mm

- Max. Outer Diameter -

- Max. Wire Feed Speed: 120m/min

- Max. Production Rate -

- Feed Roller: 2 Groups

- Feed Servo Motor: 2.7 kW

- Quill Servo Motor: 1.0 kW

- Wire Rotation Servo Motor: 2.7 kW

- Cam Servo Motor: 2.7 kW

- Spinner Servo Motor: 0.4 kW

- Air Compressor System (Air pressure): 0.2-0.4 Pa

- Air Compressor System (Air cylinder): 5

- Air Compressor System (Probe): 5

- Power: 3P 380V 50/60Hz

- Dimension (L*W*H): 1450*1250*1900 mm

- Weight: 1500 kg

Request a quote

Features

- Through CNC code, the wire feed system and cam drive system are synchronously controlled to achieve 24h accurate operation.

- 5-Axis CNC spring former adopts Taiwan CNC control system and advanced Japanese industrial servo motor system.

- Customized configuration includes spinner internal/external, servo controlled left/right hand (according to customer needs).

- This spring former features high precision, fast speed and stable production capacity.

Get in Touch

KCMCO is at the forefront of technology, specializing in R&D, design, manufacture and sales of various automatic spring machines and wire forming machines. At KCMCO, we offer a variety of spring making equipment including CNC spring forming machine, high speed spring coiling machine, automatic wire feeding machine and tufting machine. Our metal forming machines are mainly used to produce tension springs, compression springs, torsion springs, single cone spring, convex concave spring, lock spring, special-shaped spring and forming of complex parts, which serves a wide range of applications, such as automotive industry, instrumentation, etc.