2/3-Axis CNC Spring Coiler

2/3-Axis CNC spring coiler adopts Japanese servo motor and Taiwan CNC control system. Its feed axis and cam axis can operate independently or synchronously. This spring coiler is ideal for processing wires with a diameter of 0.15-0.8mm. Besides, it’s equipped with left- and right-hand rotary tool holders and torsion mechanism for the production of various types of compression springs, torsion springs, tension springs, etc.

This spring coiler comes with high forming speed, high precision and low noise. The third axis is specially added for the pushing rod cutter, which not only facilities the forming of springs, saves adjusting time and wire cost, but also has the ability to produce complex products.

0.8-2.6mm Spring Coiling Machine, 120m/min, 2 axes, KCT-26A

- Model: KCT-26A

- Number of Axis: 2

- Wire Diameter: Φ0.8-2.6mm

- Max. Outer Diameter: Φ70mm

- Max. Wire Feed Speed: 120m/min

- Wire Feeding Length: 120m/min

- Max Production Rate: 200pcs/min

- Feed Roller: 2Groups

- Feed Servo Motor: 2.7kW

- Cam Servo Motor: 2.7kW

- Pitch Servo Motor -

- Upper/lower Cutter Servo Motor -

- Air Compressor System (Air pressure): 0.2-0.4Pa

- Air Compressor System (Air cylinder): 2

- Air Compressor System (Probe): 2

- Power: 3P/380V 50/60HZ

- Dimension (L*W*H): 1150*1300*1750mm

- Weight: 1000kg

Request a quote

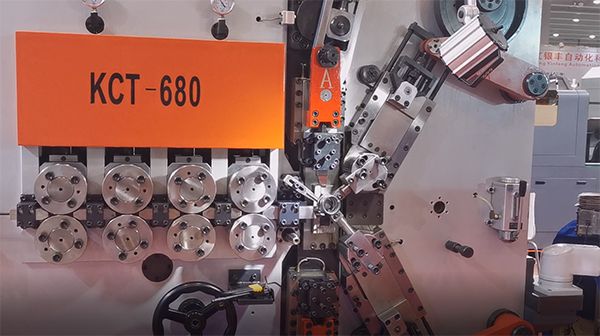

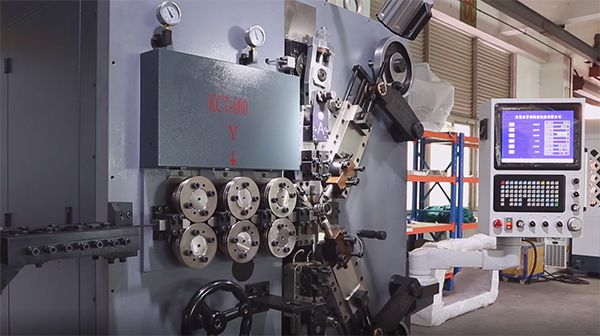

0.15-0.8mm Spring Coiling Machine, 400pcs/min, 2 axes, KCT-8C

- Model: KCT-8C

- Number of Axis: 2/3 (Optional)

- Wire Diameter: Φ0.15-0.8mm

- Max. Outer Diameter: Φ20mm

- Max. Wire Feed Speed: Unlimited

- Max. Production Rate: 400pcs/min

- Feed Roller: 1Group

- Feed Servo Motor: 1.0kW

- Cam Servo Motor: 1.0kW

- Air Compressor System (Air pressure): 0.2-0.4Pa

- Air Compressor System (Air cylinder): 2

- Air Compressor System (Probe): 2

- Power: 3P/380V 50/60HZ

- Dimension (L*W*H): 900*1000*1500mm

- Weight: 350kg

Request a quote

Features

- Optional length detection function is available.

- The standard axes include feed axis, cam axis and pitch axis. These axes can operate independently or synchronously.

- This spring coiler adopts Taiwan CNC control system, Japanese industrial servo motor and high precision bearings, as well as left/right rotary tool holder and torsion mechanism (customized).

Get in Touch

KCMCO is at the forefront of technology, specializing in R&D, design, manufacture and sales of various automatic spring machines and wire forming machines. At KCMCO, we offer a variety of spring making equipment including CNC spring forming machine, high speed spring coiling machine, automatic wire feeding machine and tufting machine. Our metal forming machines are mainly used to produce tension springs, compression springs, torsion springs, single cone spring, convex concave spring, lock spring, special-shaped spring and forming of complex parts, which serves a wide range of applications, such as automotive industry, instrumentation, etc.