Spring Machines

Industries

KCMCO spring machines serve a wide range of applications, including medical, automotive, fitness, aerospace, robotics, consumer products. As long as these products have the spring parts, our wire forming machinery can cover your need!

-

- Medical SpringsCompression,extension,torsion,and conical coil springs are widely used for medical devices in the medical industry.The most popular spring material type used for medical devices is stainless steel 316. Stainless steel 316 is a very clean material type and features good strength and non-magnetic properties up to 90%. You may find stainless steel medical springs in auto-injector syringes or inhalers. These springs can also be very small coil springs depending on the device they'll be installed into. These small springs may also be referred to as micro springs. The smallest wire diameter for medical springs we're able to manufacture is of 0.006” (inch). Our spring making machine KCT-808 with 8 axis is a type of high speed precision spring coiling machine,which can manufacture the medical springs you need.

-

- Springs for Consumer ProductsSprings of every shape and size make the products we use every day work. From ball point pens to jewelry to recyclable containers, we rely on spring manufacturers for the spring technology that is integral to basic engineering.

-

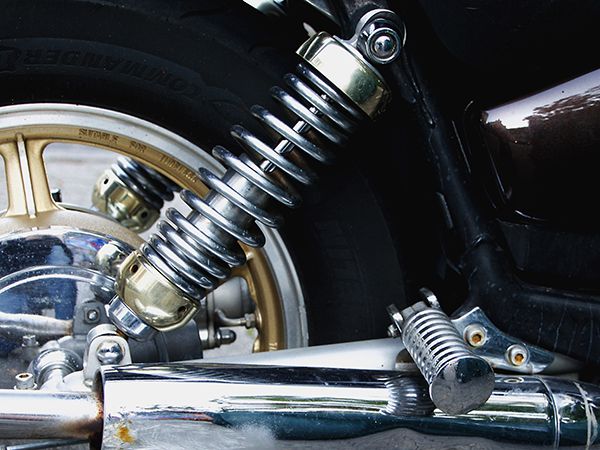

- Automotive SpringsWire forms and custom fabricated springs are important components that go into the assembly of automotive parts and vehicles. For many years, Kaichuang (KCMCO) spring making machineries have manufactured precision springs and wire forms for the automotive industry, and today we continue to provide quality and excellence in custom spring fabrication.

-

- Exercise SpringsCompression springs, torsion springs, and extension springs have found wide applications in the fitness industry. Kaichuang offers various spring making machines with custom designs to meet specific spring manufacturing needs. High performing, reliable and durable springs are crucial

-

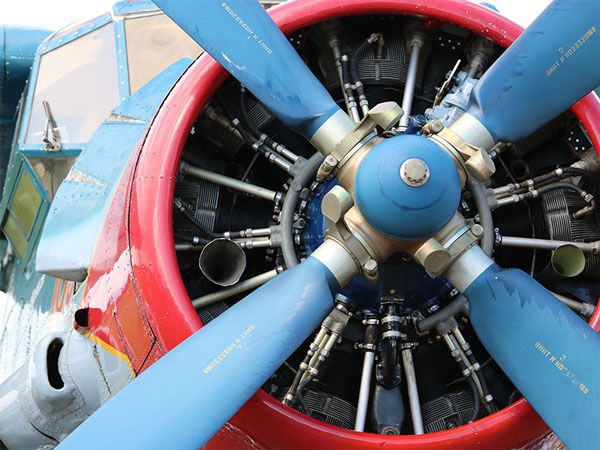

- Aerospace SpringsAerospace applications necessitate parts that can meet unique, demanding challenges as aircrafts must work to perfection under very harsh conditions, and the aircraft is only as good as the parts that make it up. These unique demands of the aerospace industry require a variety of springs and other parts, from compression springs to metal forms using, KCMCO spring making machine KCT-1280WZ with 12 axis can support your spring manufacturing needs.

-

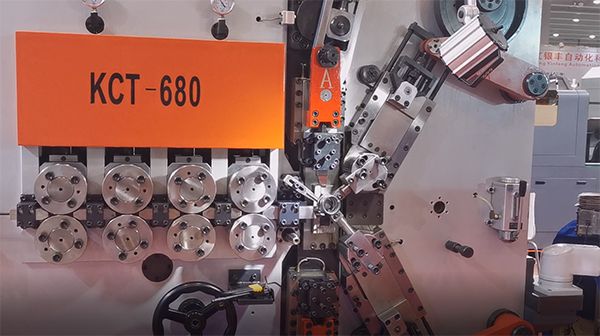

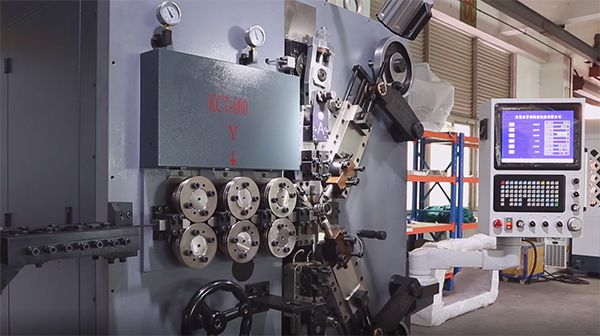

- Springs in RoboticsEvery component in robot manufacturing is vital for the proper functioning of the machine, especially regarding its movements. Springs are at the core of robotic movement, and essential for smooth and human-like mobility. Modern advancements due to countries like China investing in robotics are seeing mechanisms develop at an impressive rate. KCMCO CNC spring making machines can be used to manufacture such kind of valuable springs, including CNC spring coiling machine KCT-816, KCT-660 and CNC spring wire forming & rotation machine KCT-1260WZ, KCT-1445WZ.

KCMCO is at the forefront of technology, specializing in R&D, design, manufacture and sales of various automatic spring machines and wire forming machines. At KCMCO, we offer a variety of spring making equipment including CNC spring forming machine, high speed spring coiling machine, automatic wire feeding machine and tufting machine. Our metal forming machines are mainly used to produce tension springs, compression springs, torsion springs, single cone spring, convex concave spring, lock spring, special-shaped spring and forming of complex parts, which serves a wide range of applications, such as automotive industry, instrumentation, etc.