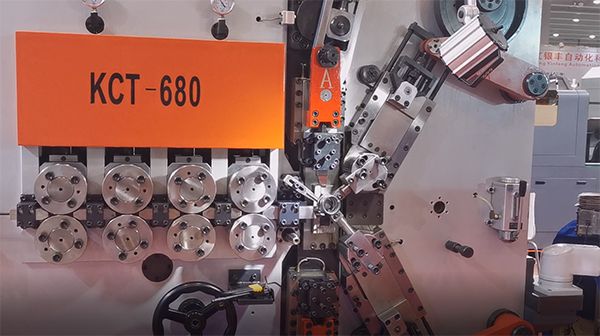

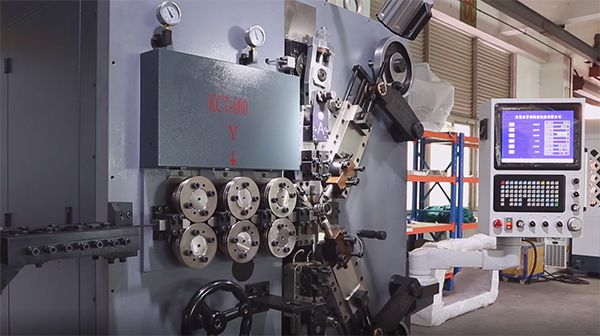

10-Axis Camless CNC Spring Forming Machine, KCT-1008A

This spring forming machine integrates a Taiwanese CNC control system with Japanese imported servo motors featuring a camless and rockerless design. It integrates a crankshaft forming system, a wire feeding system, a rotation system, and a straightening system, allowing for efficient spring production. Each of the servo axes operates independently, which realizes synchronous or asynchronous operation without interference.

Designed for the production of small-diameter springs, it is widely used in industries such as medical devices, precision instruments, measuring equipment, and electronics. The CNC spring forming machine is designed with eight forming axes that combine the advantages of modern camless technology with the reliability of traditional cam-driven systems. This feature enhances its overall operational accuracy and efficiency for the production of intricate spring designs. The spring forming machine can also be equipped with a coiling attachment, enabling it to handle more complex tasks and produce a wider variety of spring types and wire forms.

| Model | KCT-1008A |

| Number of Axes | 10 axes |

| Wire Diameter | ⌀0.1-0.8mm |

| Wire Feed Speed | 0-90m/min |

| No. of Wire Feed Rollers | 1 set |

| Wire Feed Servo Motor | 0.75kW |

| Forming Servo Motor | 0.75kW*8 |

| Rotation Servo Motor | 0.75kW |

| Coiling Servo Motor (Optional) | 0.15kW |

| Wire Feed Value | ±0.01-99999.99mm |

| Screen Display | Multi-color, Chinese/English |

| Data Storage Capacity | 1000pcs |

| Air Pressure Range | 0.2-0.4Pa |

| Air Cylinder/Probe | 5 pairs |

| Overall Dimensions (L*W*H) | 660*1100*1650mm |

| Weight | 900kg |

| Power Supply | 3P-380V 50/60Hz |

- Equipped with the Taiwanese CNC control system and Japanese Yaskawa servo motors, resulting in quick response times and better synchronization performance

- Utilizes a 10-axis design including eight axes for forming and one axis for rotation powered by servo drive (bus version), while the wire feeding axis controlled by a servo drive (pulse version), providing enhanced operational stability

- With the integration of the advantages of cam and camless structures, its cumulative errors during forming operations are significantly reduced. The use of eccentric cam drives with near-zero inertia results in higher production precision and faster operating speeds.

- Its mechanical precision and durability are enhanced by the diamond-shaped slide design. This adjustable diamond structure ensures that the wear gap is controlled within 0.005mm for over ten years.

- The wire feed device employs oil-immersed lubrication system, assuring noiseless operation with continuous lubrication of the wire feeding gears. This not only reduces gear wear but also guarantees long-term wire feeding accuracy.

- The wire feeding gears are manufactured to grade 4 standards, and the slides are made from Japanese SLD steel, treated to HRC 59-62 through vacuum processing, followed by ultra-deep cryogenic treatment at -200°C. This ensures long-lasting precision and durability.

- Features a 100mm long mandrel, making it ideal for the production and manufacturing of high-precision spring products

- Designed with an oil recycling system that not only recycles waste oil but also prevents overflow or leakage when lubricating oil passes through the oil grooves.