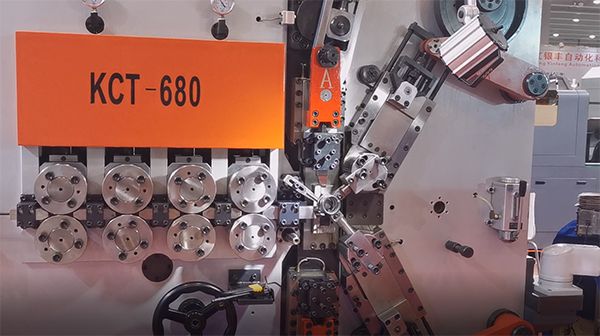

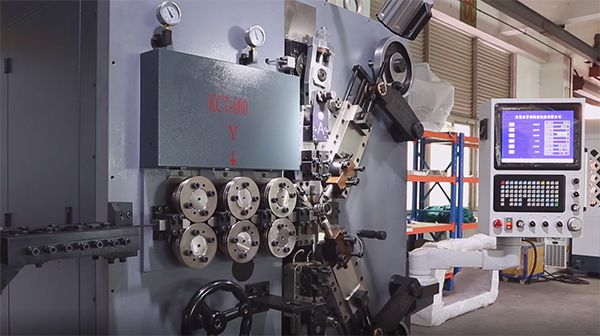

12-Axis CNC Spring Making Machine

12-Axis CNC spring making machine features unique camless and arm-less design. The tool holder is independently controlled by eight servo motors. The spring former is equipped with eight tool holder, wire feed, quill, wire rotation, spinner axes as standard. This metal forming machine is ideal for wire diameters of 0.3 to 8.0mm, with a maximum feeding speed of 100 m/min and a feeding accuracy of ≤0.1 mm. It is specially designed for producing compression spring, tension spring, torsion spring, scroll spring, tower spring, flat spring, special-shaped spring, wire forms, etc.

0.3-2.5mm Spring Making Machine, Computer Controlled, 12-axis, without Cam, KCT-1220WZ

- Model: KCT-1220WZ

- Number of Axis: 12 axes

- Wire Diameter: ⌀ 0.2~2.5mm

- Max Outside Diameter: ⌀ 60mm

- Max Feeding Length: Unlimited

- Max Feeding Speed: 120 m/min

- Max Production Rate: 70 pcs/min

- Feeding Roller: 2 Pairs

- Feeding Servo Motor: 2.9 kW

- Forming Servo Motor: 0.75 kW *8

- Quill Servo Motor: 0.75 kW

- Wire Rotation Servo Motor: 2.9 kW

- Spinner Servo Motor: 0.4 kW

- Reducer of Wire Forming: Ratio 1/10

- Reducer of Wire Rotation: Ratio 1/5

- Spinner Reducer: Ratio 1/3

- AC Power : 3~380VAC 50Hz

- Dimension (L*W*H): 1600x1120x1750mm

- Weight: 1800kg

Request a quote

3.0-8.0mm Spring Forming Machine, CNC Control, 12-axis, without Cam, KCT-1280WZ

- Model: KCT-1280WZ

- Number of Axis: 12 (Max. 18 axes)

- Wire Diameter: ⌀ 3.0-8.0 mm

- Max Outside Diameter: ⌀ 130mm

- Max Feeding Speed: 100 m/min

- Spring Index: 4

- Feeding Roller: 4 Groups

- Feeding Servo Motor: 15 kW

- Quill Servo Motor: 1.8 kW

- Wire Rotation Motor: 7.5 kW

- Forming Servo Motor: 4.4 kW *8

- Spinner Servo Motor: 1.3 kW

- Air Compressor System (Air pressure): 0.2-0.4Pa

- Air Compressor System (Air cylinder): 5

- Air Compressor System (Probe): 5

- Power Source: 3P/380V 50/60Hz

- Machine Dimension (L*W*H): 5000*2300*2800mm

- Weight: 13000KG

Request a quote

2.0-6.0mm Spring Making Machine, Computer Controlled, 12-axis, without Cam, KCT-1260WZ

- Model: KCT-1260WZ

- Number of Axis: 12 (Max. 18 axes)

- Wire Diameter: ⌀ 2.0-6.0 mm

- Max. Outer Diameter: ⌀ 120 mm

- Max. Feeding Speed: 100 m/min

- Spring Index: 4

- Feeding Roller: 4 Groups

- Feeding Servo Motor: 7.5kW

- Quill Servo Motor: 1.8 kW

- Wire Rotation Servo Motor: 5.5 kW

- Forming Servo Motor: 4.4 kW *8

- Spinner Servo Motor: 1.8 kW

- Air Compressor System (Air pressure): 0.2-0.4 Pa

- Air Compressor System (Air cylinder): 5

- Air Compressor System (Probe): 5

- Power: 3P/380V 50/60Hz

- Dimension (L*W*H): 3400*1800*2300 mm

- Weight: 6000 kg

Request a quote

1.2-4.5mm Spring Forming Machine, CNC Control, 12-axis, Without Cam, KCT-1245WZ

- Model: KCT-1245WZ

- Number of Axis: 12 axes

- Wire Diameter: ⌀1.2-4.5 mm

- Max Outside Diameter: ⌀120 mm

- Max Feeding Speed: 120 m/min

- Spring Index: 4

- Wire Feeding Wheel Count: 3 Pairs

- Feeding Motor SGMGV-44A: 4.4 kW

- Quill Motor SGMGV-15A: 1.3 kW

- Wire Rotation Motor SGMGV-44A : 4.4 kW

- Forming Motor SGMGV-13A: 1.3 kW *8

- Spinner Motor SGMGV-09A: 1.0 kW

- Wire Forming Reducer: VRB115 Ratio 1:15

- Spinner Reducer: VRB090 Ratio 1:10

- Wire Rotation Reducer: VRB140 Ratio 1:3

- Dimension (L*W*H): 2400x1600x1900 mm

- Weight: 5000kg

- Power Source: 3-380VAC 50Hz

Request a quote

Features

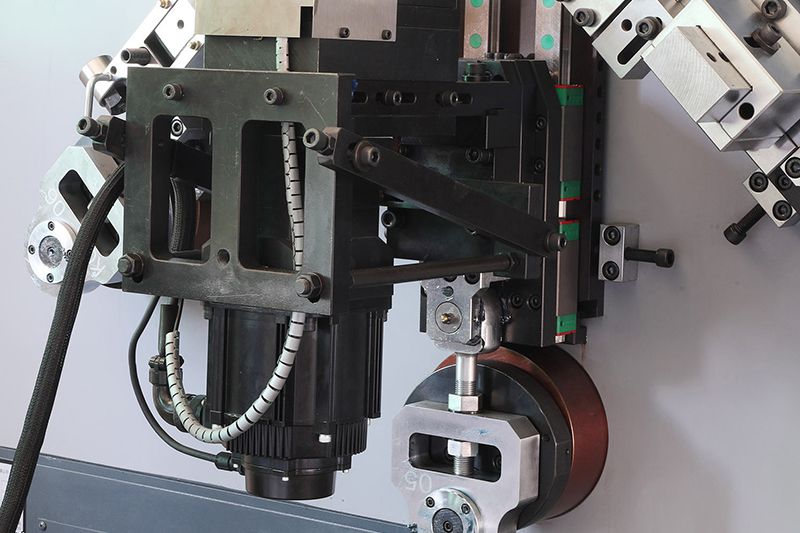

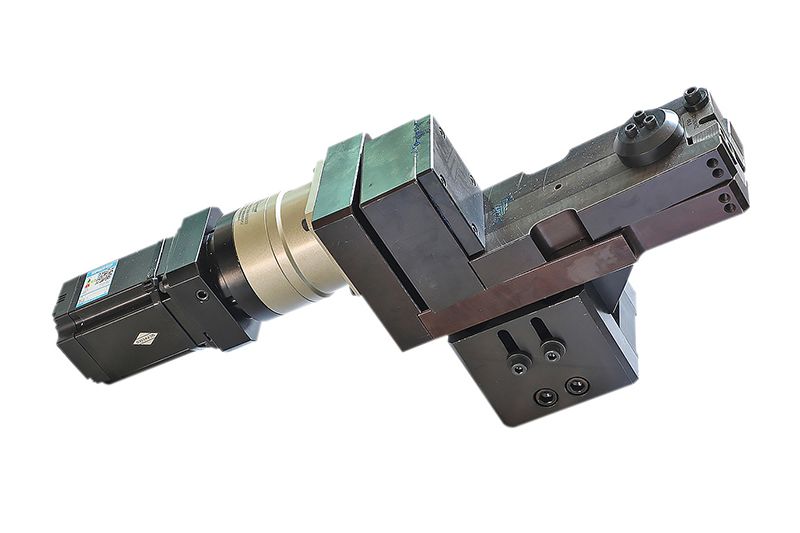

- Tool holder is independently controlled by eight sets of Yaskawa servo motors and the motor is independently driven by VRB reducer.

- Through CNC control system, the wire feed and rotation system are synchronously controlled to achieve a feeding accuracy of ≤0.1mm.

- Wire feed system is controlled by computer and the feeding unit is 0.01mm, allowing for a maximum feeding of 99999.99 units.

- 360-degree rotary feeding system: The special-shaped spring is rotated to the required angle in the production process, so as to replace the Cam for rotation, which shortens the time of adjusting the machine and the situation of insufficient tools.

- Independent electrical box is safe and convenient to maintain and inspect.

- Hydraulic cutting device is optional based on your demands, offering low cutting noise and zero damage to the mandril and machine.

Get in Touch

KCMCO is at the forefront of technology, specializing in R&D, design, manufacture and sales of various automatic spring machines and wire forming machines. At KCMCO, we offer a variety of spring making equipment including CNC spring forming machine, high speed spring coiling machine, automatic wire feeding machine and tufting machine. Our metal forming machines are mainly used to produce tension springs, compression springs, torsion springs, single cone spring, convex concave spring, lock spring, special-shaped spring and forming of complex parts, which serves a wide range of applications, such as automotive industry, instrumentation, etc.